1. Introduction

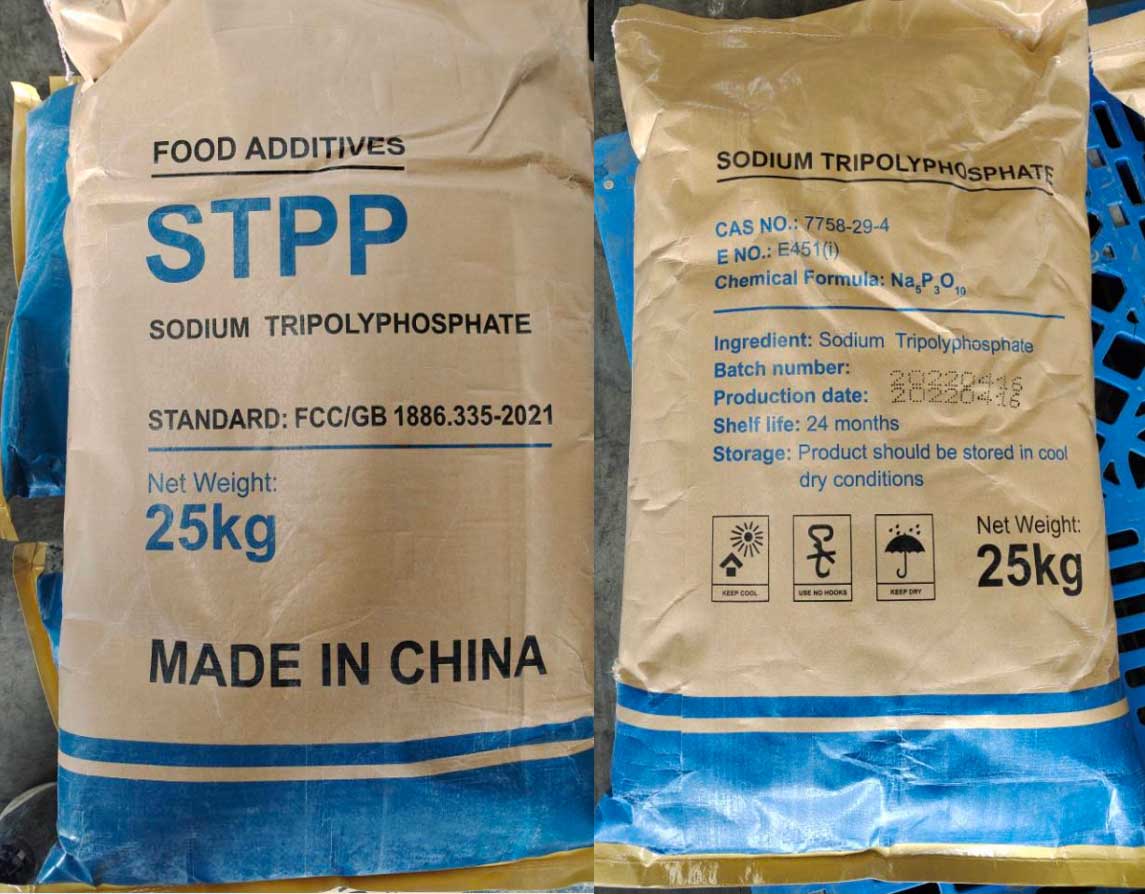

Sodium Tripolyphosphate (STPP, Na₅P₃O₁₀) is widely used as a food additive in the meat and seafood industries. It plays a critical role in improving texture, moisture retention, and shelf life while enhancing the overall quality of processed products. Due to its excellent water-binding and emulsifying properties, STPP is commonly found in processed meats, poultry, and seafood products.

2. Functions and Effects of STPP in Meat and Seafood Processing

2.1 Moisture Retention (Water Binding)

STPP increases the water-holding capacity (WHC) of meat and seafood by enhancing protein hydration.

Reduces cooking loss by preventing excessive moisture loss during heat processing.

Keeps meat and seafood juicy and tender, improving consumer appeal.

2.2 Texture and Firmness Improvement

In processed meats (e.g., ham, sausages, and bacon), STPP helps stabilize muscle proteins, creating a firmer texture.

In seafood, such as shrimp and fish fillets, it prevents excessive softening and breakage.

2.3 pH Regulation and Protein Functionality Enhancement

STPP increases pH, shifting meat proteins away from their isoelectric point, thereby improving protein solubility and water-binding ability.

Helps improve emulsification in products like hot dogs and meatballs.

2.4 Prevention of Drip Loss and Freezer Burn

Reduces thawing losses in frozen meat and seafood by minimizing the release of liquid during defrosting.

Protects against freezer burn, preserving the product’s quality and freshness.

2.5 Color and Flavor Stabilization

Prevents oxidative rancidity and discoloration in stored meat and seafood.

Helps maintain a natural and appealing color by reducing the impact of oxidation.

3. Recommended Dosage of STPP in Meat and Seafood Processing

The optimal dosage of STPP depends on the specific product and its processing conditions. Overuse can lead to a soapy taste or excessive water retention, negatively affecting the product’s quality.

| Product Type | Recommended STPP Dosage (%) (by total weight) |

|---|---|

| Processed meats (ham, sausages, bacon) | 0.3% – 0.5% |

| Poultry products (chicken breast, turkey) | 0.2% – 0.5% |

| Shrimp, fish fillets | 0.3% – 0.8% |

| Surimi and seafood-based products | 0.3% – 0.6% |

Regulations: Many countries have limits on STPP usage in food processing. For example, the EU limits STPP in seafood to a maximum of 0.5% (as phosphate content), while the US FDA classifies it as Generally Recognized As Safe (GRAS) when used within approved limits.

4. How to Use STPP in Meat and Seafood Processing

4.1 Preparation of STPP Solution

STPP should be dissolved in cold water before application.

A typical STPP solution concentration is 3% – 5% (30g – 50g per liter of water).

Stir well until fully dissolved to ensure even distribution.

4.2 Application Methods

(A) Injection (for Processed Meat & Poultry)

Brine injection is commonly used in ham, chicken breast, and turkey.

Inject 10% – 20% brine solution (containing STPP) into the meat before tumbling.

Helps improve juiciness and texture while maintaining product weight.

(B) Tumbling and Marination (for Meats & Seafood)

Meat or seafood is placed in a vacuum tumbler with an STPP brine solution.

Tumbling time: 30 – 90 minutes to allow better absorption and protein activation.

Improves moisture retention and texture uniformity.

(C) Soaking (for Shrimp, Fish Fillets, and Surimi)

Seafood products are soaked in an STPP solution for 15 – 30 minutes.

This method enhances firmness, reduces drip loss, and prevents freezer burn.

Excess STPP must be removed by rinsing with clean water before freezing or cooking.

5. Potential Concerns and Best Practices

✅ Do not exceed regulatory limits – Excessive STPP can result in a slimy texture, off-flavors, and consumer rejection.

✅ Ensure even distribution – Poor mixing can cause localized high concentrations, affecting taste and texture.

✅ Combine with other phosphates for better functionality – Blending STPP with sodium hexametaphosphate (SHMP) or sodium pyrophosphate (TSPP) can enhance water retention without excessive softening.

✅ Avoid over-soaking – Prolonged soaking in STPP solutions can lead to excessive moisture retention, giving meat a spongy texture.

6. Conclusion

Sodium Tripolyphosphate (STPP) is a crucial additive in meat and seafood processing, enhancing moisture retention, texture, and stability. Proper dosage and application techniques ensure high-quality, appealing, and cost-effective processed products. However, food manufacturers must adhere to regulatory guidelines to avoid overuse and potential quality issues.