1. Introduction to STPP in Detergents

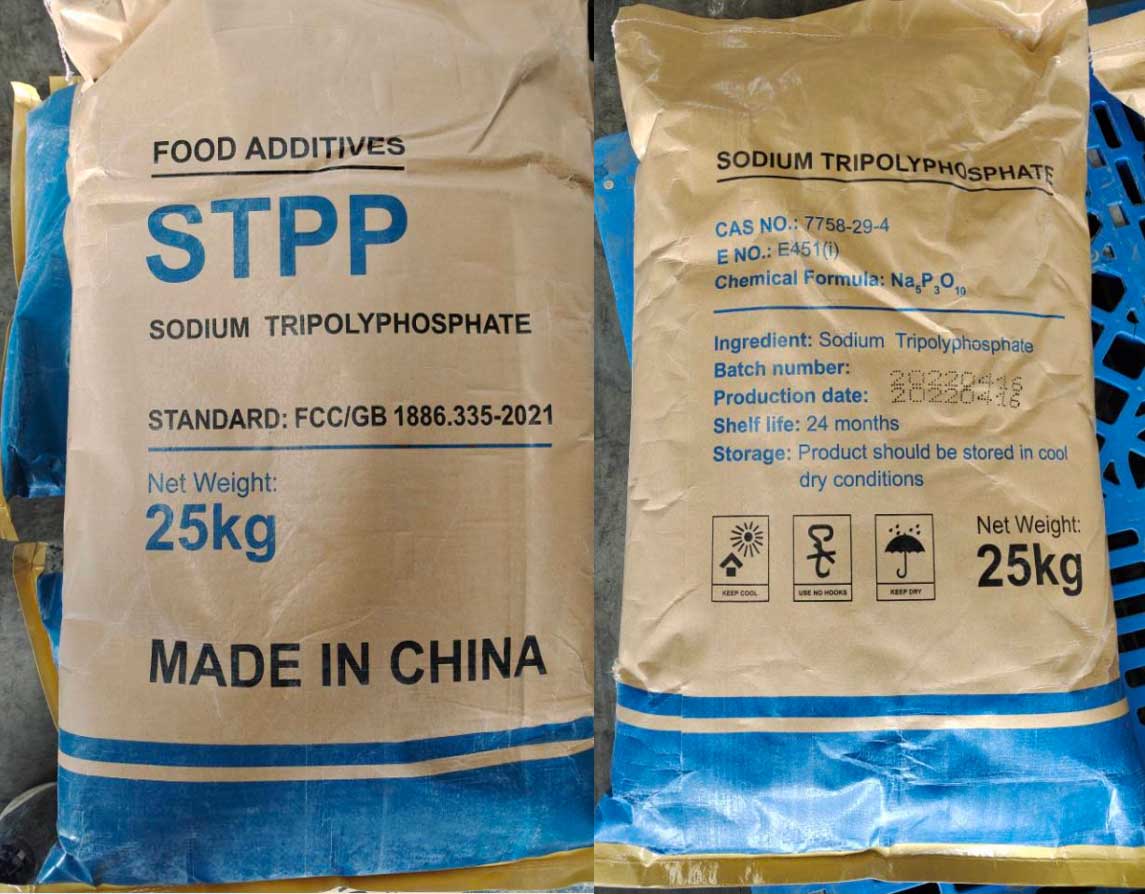

Sodium Tripolyphosphate (STPP, Na₅P₃O₁₀) is one of the most widely used builders in detergent powders. It plays a crucial role in enhancing cleaning efficiency, improving water softening, stabilizing detergent formulations, and preventing soil redeposition. Due to its strong chelating ability, STPP helps detergents work more effectively, even in hard water conditions.

2. Functions of STPP in Detergent Powder

2.1 Water Softening (Chelating Agent)

Hard water contains calcium (Ca²⁺) and magnesium (Mg²⁺) ions, which reduce the effectiveness of surfactants.

STPP binds to these metal ions, preventing them from interfering with surfactant activity, ensuring better lathering and cleaning.

2.2 Emulsification and Suspension of Dirt

Helps break down greasy stains by dispersing fats and oils in water.

Suspends dirt and soil in water, preventing them from redepositing on fabrics.

2.3 pH Buffering

Maintains the pH level of detergent solutions in an optimal range (pH 9–10.5), improving cleaning efficiency.

2.4 Preventing Soap Scum Formation

STPP prevents insoluble soap scum by reacting with calcium and magnesium, keeping the detergent fully active.

2.5 Anti-Caking Agent

Reduces moisture absorption in powder detergents, ensuring free-flowing granules.

3. Dosage of STPP in Detergent Powder

The amount of STPP used in detergent formulations depends on the desired cleaning performance, water hardness level, and cost considerations. Below are general dosage guidelines:

| Detergent Type | STPP Dosage (% by weight) |

|---|---|

| High-quality premium detergents | 25% – 35% |

| Standard household detergents | 15% – 30% |

| Low-cost or phosphate-reduced detergents | 5% – 15% |

| Eco-friendly or phosphate-free detergents | 0% (Replaced by Zeolites or Citrates) |

Note: Many countries are reducing or banning STPP in detergents due to environmental concerns (eutrophication in water bodies). Alternative builders like zeolites, sodium carbonate, or citrates are often used instead.

4. How to Use STPP in Detergent Powder Production

Step 1: Preparing the Raw Materials

Gather all necessary ingredients, including:

Surfactants (e.g., LABSA, SLES, Soap)

Builders (e.g., STPP, Sodium Carbonate, Zeolite)

Fillers (e.g., Sodium Sulfate)

Enzymes (e.g., Protease, Amylase)

Bleaching Agents (e.g., Sodium Percarbonate)

Fragrances & Colorants

Step 2: Mixing Dry Ingredients

In a high-speed blender or ribbon mixer, mix STPP, Sodium Carbonate, Sodium Sulfate, and other dry ingredients.

Ensure uniform distribution to prevent localized over-concentration.

Step 3: Addition of Surfactants & Liquid Components

Slowly add liquid surfactants (LABSA, SLES) into the dry mixture.

Ensure proper mixing to avoid clumping and ensure uniform distribution.

Spray-dry the mixture (if using a spray-drying process).

Step 4: Granulation & Drying (If Needed)

If the detergent requires granules, pass the mixture through a granulator to create uniform particles.

If a dry-blended process is used, move directly to the final stage.

Step 5: Addition of Perfumes, Optical Brighteners, and Enzymes

Add heat-sensitive ingredients like enzymes, perfumes, and colorants at the final stage.

Mix gently to prevent degradation of these ingredients.

Step 6: Packaging

The final detergent powder is sieved to remove lumps.

Packaged in moisture-proof bags or containers for storage and sale.

5. Other Key Components in Detergent Powder

A well-balanced detergent formulation consists of multiple ingredients, each serving a specific function:

5.1 Surfactants (Cleansing Agents)

Anionic Surfactants (e.g., LABSA, SLES): Provide strong cleaning power and foaming properties.

Non-Ionic Surfactants (e.g., Alcohol Ethoxylates): Improve grease removal and work in low-foaming detergents.

Soap (Fatty Acid Salts): Used in some detergents for additional cleaning power.

5.2 Builders (Water Softeners & Dirt Dispersers)

STPP (Sodium Tripolyphosphate) – Strong water softener and dispersant.

Zeolites (Phosphate-Free Alternative) – Replace STPP in eco-friendly detergents.

Sodium Carbonate (Soda Ash) – Softens water and maintains alkalinity.

Sodium Silicate – Helps prevent corrosion in washing machines.

5.3 Fillers (Dilutants & Carriers)

Sodium Sulfate (Na₂SO₄) – Reduces bulk density and improves powder flow.

Sodium Chloride (NaCl, Table Salt) – Used in low-cost detergents.

5.4 Bleaching Agents (Stain Removal & Whitening)

Sodium Percarbonate (Oxygen Bleach) – Releases hydrogen peroxide for stain removal.

Sodium Perborate – An alternative to percarbonate, used in European formulations.

5.5 Enzymes (Biological Stain Removal)

Protease – Breaks down protein-based stains (e.g., blood, egg).

Amylase – Removes starch-based stains (e.g., sauces, baby food).

Lipase – Targets greasy and oily stains.

5.6 Optical Brighteners (Whitening Agents)

Absorb UV light and reflect blue light, making clothes appear brighter.

5.7 Fragrances & Colorants

Added to improve consumer appeal and provide a pleasant washing experience.

6. Conclusion

STPP is an essential component in detergent powders, significantly improving cleaning performance, water softening, and suspension of dirt.