Phosphates play a critical role in the meat industry due to their ability to improve the quality, functionality, and shelf life of meat products. Here are the key applications of phosphates in meat processing:

1. Water Retention

Improved Water-Holding Capacity: Phosphates increase the ability of muscle proteins to bind water, reducing cooking loss and improving juiciness.

Reduced Drip Loss: They minimize moisture loss during storage, keeping meat products visually appealing and weight consistent.

2. pH Adjustment

Protein Solubilization: Phosphates increase the pH of meat, bringing it closer to the isoelectric point of muscle proteins. This enhances protein solubility, which is essential for binding water and fat.

Improved Binding: By raising the pH, phosphates improve the emulsifying capacity of proteins, resulting in better binding of ingredients in processed meats.

3. Texture Improvement

Tenderization: Phosphates help break down muscle fibers and soften the texture of meat, making it more palatable.

Uniform Texture in Processed Meats: In emulsified products like sausages and hot dogs, phosphates ensure a consistent and smooth texture.

4. Emulsification

Fat Stabilization: Phosphates facilitate the binding of fat and water, preventing fat separation in products like sausages, luncheon meats, and pâtés.

Improved Product Stability: This results in a stable and uniform structure, enhancing the overall sensory quality.

5. Shelf Life Extension

Inhibition of Rancidity: Phosphates act as antioxidants by chelating metal ions (e.g., iron and copper) that catalyze lipid oxidation, thereby delaying spoilage and off-flavors.

Microbial Inhibition: Some phosphates can slow microbial growth, improving the safety and shelf life of meat products.

6. Yield Improvement

Enhanced Product Weight: By retaining more water during cooking, phosphates help increase product yield, which is economically beneficial for manufacturers.

Reduced Processing Losses: Phosphates reduce shrinkage during thermal processing.

7. Color Stability

Enhanced Color Retention: Phosphates help maintain the natural red or pink color of fresh and processed meats by stabilizing the myoglobin pigment.

Prevention of Discoloration: They reduce oxidation, which can lead to undesirable gray or brown hues.

8. Applications in Specific Meat Products

Cured Meats (e.g., ham, bacon): Phosphates improve brine retention, enhance curing efficiency, and create a firm, uniform texture.

Sausages: They ensure a smooth texture, better binding of water and fat, and reduced cooking loss.

Poultry Products: Phosphates are used in marinated chicken and turkey to improve juiciness, texture, and cooking yield.

Processed Meats (e.g., nuggets, patties): They enhance batter stability and improve freeze-thaw characteristics.

Types of Phosphates Used in Meat Products

Sodium Phosphate: Commonly used for water retention and pH adjustment.

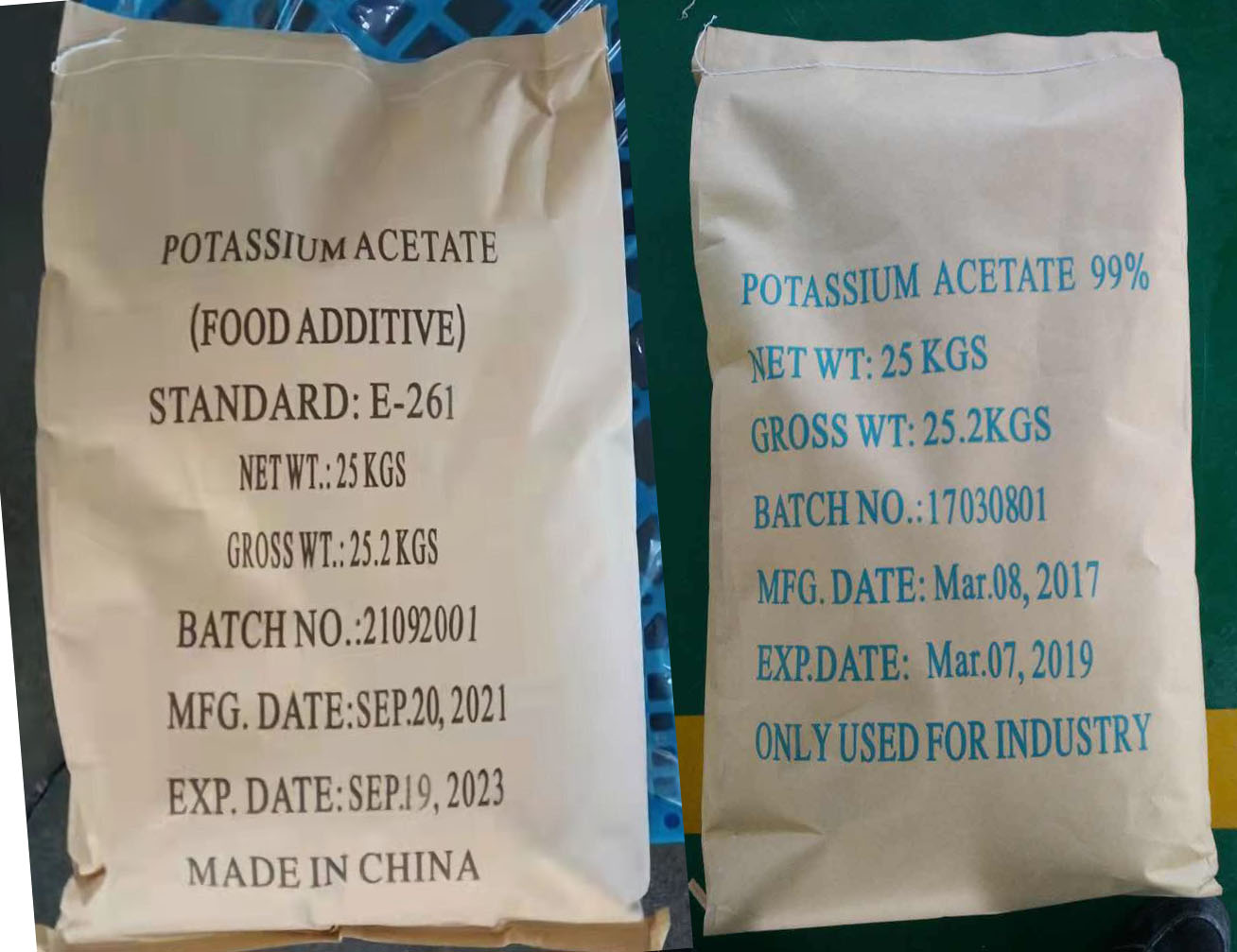

Potassium Phosphate: Suitable for low-sodium formulations.

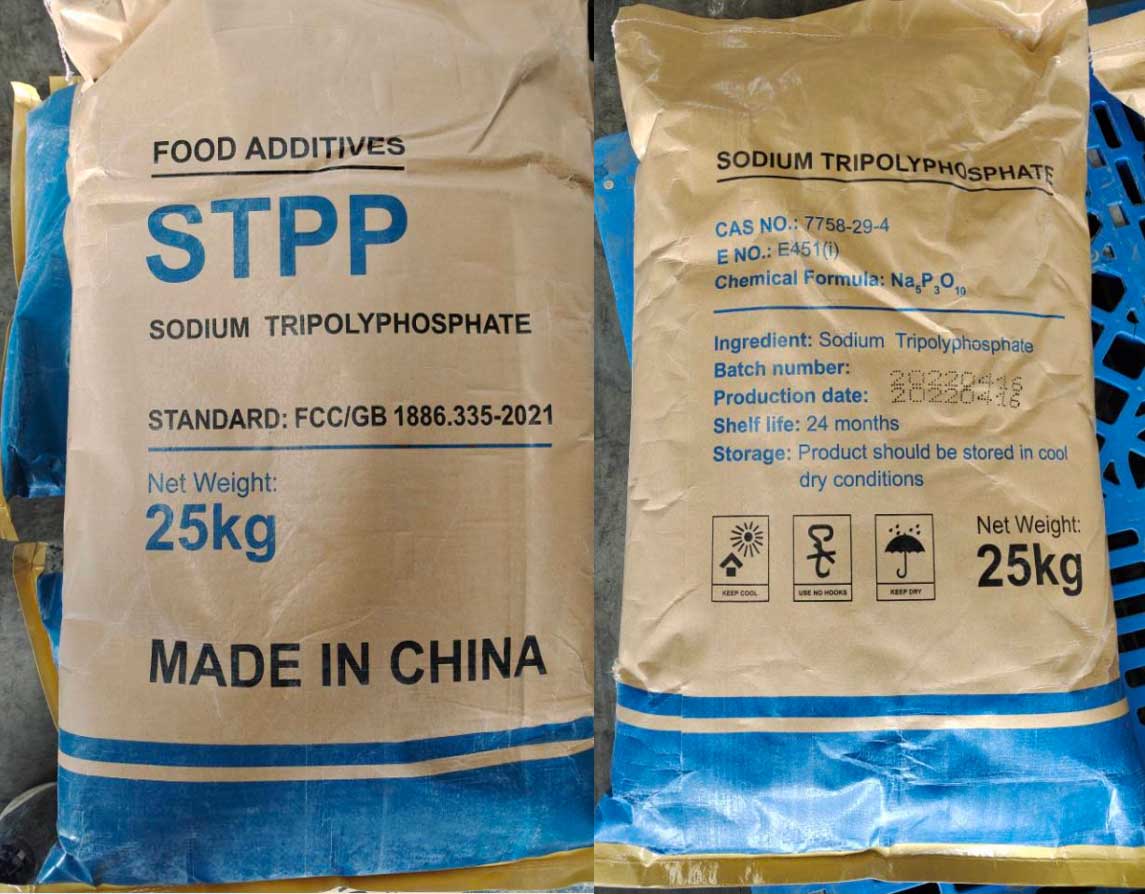

Polyphosphates: Provide strong water-binding and emulsifying properties.

Triphosphates and Hexametaphosphates: Used for their ability to improve texture and increase yield.

Phosphates are indispensable in meat processing, offering significant functional and economic benefits while ensuring product quality and consumer satisfaction.

Phosphates can be used in a wide variety of meat products due to their functional properties. Here's a breakdown of the types of meat products that benefit from phosphate applications:

1. Fresh Meat Products

Marinated Meats: Used in fresh cuts of beef, pork, poultry, and lamb to enhance water retention, improve juiciness, and tenderize the meat.

Ground Meat: In ground beef, pork, and poultry, phosphates improve water-binding capacity and prevent moisture loss during cooking.

2. Processed Meats

Sausages and Hot Dogs:

Improve binding of fat and water.

Create a smooth and consistent texture.

Prevent separation during cooking.

Deli Meats (e.g., bologna, salami, and turkey breast):

Stabilize emulsions.

Enhance slicing quality and prevent crumbling.

Reduce shrinkage during storage.

3. Cured and Smoked Meats

Ham and Bacon:

Enhance brine retention during curing.

Improve texture and moisture content.

Maintain color and inhibit spoilage.

Smoked Meats:

Retain water and improve the final yield.

Stabilize the structure of the meat post-smoking.

4. Poultry Products

Marinated Poultry (e.g., chicken breasts, turkey drumsticks):

Increase juiciness and tenderness.

Minimize moisture loss during cooking and freezing.

Processed Poultry (e.g., nuggets, patties):

Enhance batter stability and reduce frying losses.

5. Seafood

Frozen Fish and Shrimp:

Prevent moisture loss during freezing and thawing.

Improve texture and maintain firmness.

Canned Seafood:

Reduce discoloration and maintain natural flavor.

6. Ready-to-Eat and Convenience Meats

Prepared Meals (e.g., meat pies, ready-to-cook roasts):

Improve moisture retention during reheating.

Enhance texture and appearance.

Frozen and Breaded Products:

Maintain structure and reduce ice crystal damage in frozen storage.

7. Specialty Products

Plant-Based Meat Alternatives:

Stabilize emulsions and improve texture.

Enhance water-holding capacity for juicier products.

Ethnic Meat Products:

Common in sausages, kebabs, or spiced meats to maintain consistency and moisture.

Benefits Across Meat Categories

Increased cooking yield.

Improved texture and appearance.

Enhanced flavor retention.

Better storage and freeze-thaw stability.

Phosphates are versatile and can be tailored for specific applications to improve the overall quality of both fresh and processed meat products.