An oil-removing agent (or degreaser) is formulated to break down and emulsify oils, grease, and other organic substances, allowing them to be easily removed from surfaces. The composition of oil removers varies depending on the intended application (industrial, household, automotive, etc.), but they typically include a combination of surfactants, solvents, emulsifiers, and sometimes alkaline or acidic agents. Here's an overview of the key components that can make up an oil-removing agent:

1. Surfactants (Active Cleaning Agents)

Anionic Surfactants: These are the most common surfactants used in oil removers. They have negatively charged groups that interact with oil molecules, allowing them to break down the oil and disperse it in water. Examples include sodium lauryl sulfate and alkylbenzene sulfonates.

Nonionic Surfactants: These surfactants have neutral charges and are less likely to produce foaming, making them useful in industrial applications. They help solubilize oils and reduce the surface tension between water and oils. Examples include polyethylene glycol esters or alkyl polyglucosides.

Cationic Surfactants: These surfactants have positively charged groups and can also be used to aid in emulsification. They are often used in combination with anionic surfactants to improve efficiency.

2. Solvents (Organic Solvents)

Hydrocarbon Solvents: Solvents such as kerosene, mineral spirits, or white spirit are used to dissolve and break down oil and grease. These solvents work by dissolving oils into solution, making them easier to rinse off.

Terpene-based Solvents: Derived from natural sources like citrus peel, these solvents are more environmentally friendly and often used in eco-conscious formulations. Examples include d-limonene and pinene.

Alcohols: Alcohols such as isopropyl alcohol or ethanol can act as solvents in some formulations, particularly for removing oil from non-porous surfaces.

3. Emulsifiers

Polymeric Emulsifiers: These help to stabilize the mixture of oil and water by forming a stable emulsion, preventing the oil from separating. Common emulsifiers include polyethylene glycol (PEG) and sodium laureth sulfate.

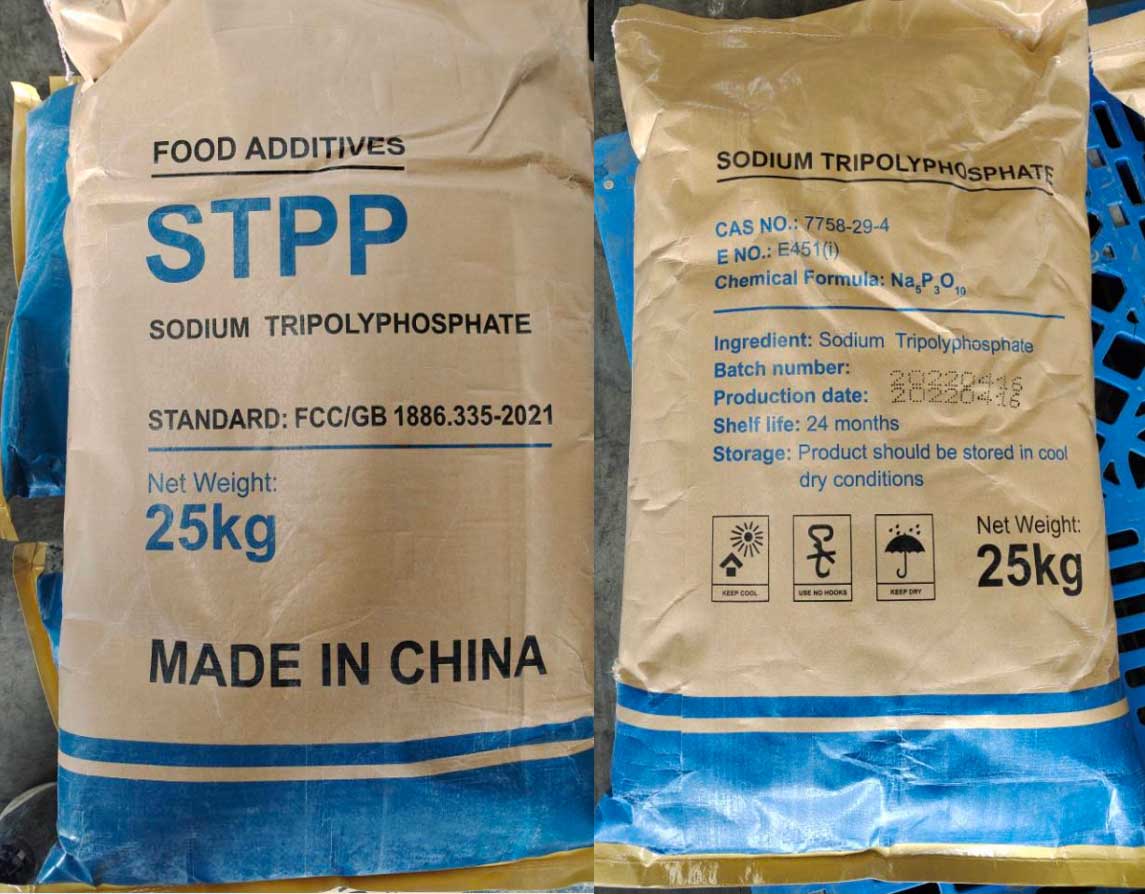

Phosphates (like Sodium Tripolyphosphate): Phosphates, such as sodium tripolyphosphate (STPP), are used as water softeners and emulsifiers to help break down grease and suspend oil in water for easy removal.

4. Alkaline or Acidic Agents

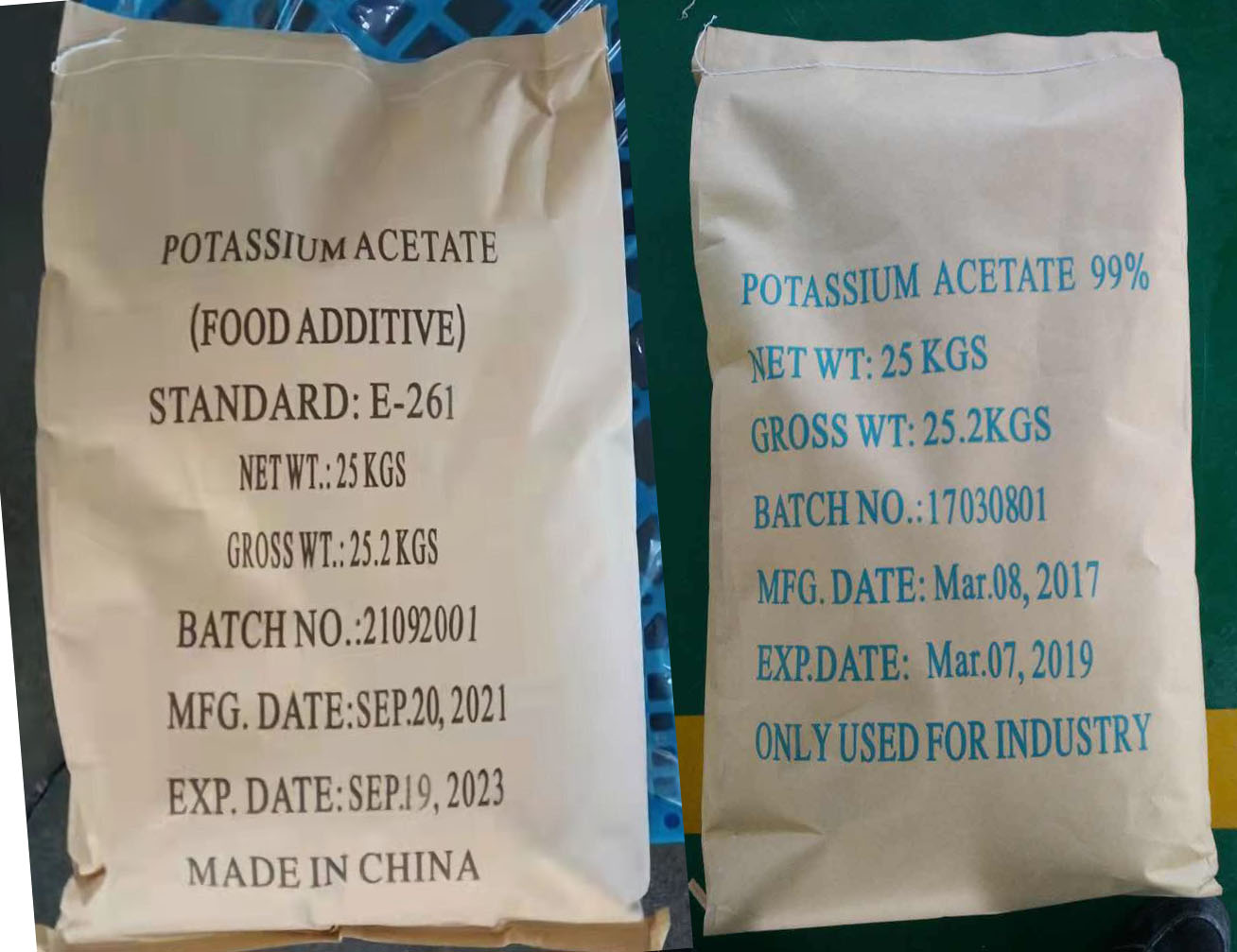

Alkaline Agents: Alkaline compounds like sodium hydroxide (caustic soda) or potassium hydroxide may be included in industrial degreasers, as they can saponify oils and fats, converting them into soap and water-soluble products. Alkaline cleaners are especially effective for greasy or fatty oils.

Acidic Agents: Some oil removers may contain weak acids like citric acid or acetic acid to help break down specific types of oil and grease, particularly in environments where inorganic residues need to be removed.

5. Chelating Agents

EDTA (Ethylenediaminetetraacetic acid): Chelating agents like EDTA or nitrilotriacetic acid (NTA) are often used to bind and sequester metal ions, which can interfere with the effectiveness of surfactants and emulsifiers. They help improve the stability and performance of the cleaner.

6. pH Adjusters

Buffers: Agents like sodium bicarbonate or ammonium hydroxide may be included to control the pH of the oil remover, optimizing its performance depending on whether the cleaner is intended for acidic or alkaline conditions.

7. Solubilizers

These ingredients help solvate or dissolve the oils into the water phase. Examples include glycerin, propylene glycol, or ethanol.

8. Fragrances and Colorants

For consumer products, fragrances and colorants may be added to enhance user experience, though these are not necessary for the oil-removal process itself.

9. Water

Water is a major solvent in most commercial degreasers and oil removers, acting as a carrier for the active ingredients and helping to rinse the oil away.

Example of Composition in an Industrial Oil Remover:

Surfactants (20-30%) – For breaking down oils and emulsifying.

Solvents (10-20%) – For dissolving oil and grease.

Emulsifiers (5-10%) – To help stabilize the oil-water mixture.

Alkaline agents (5-15%) – To break down tough oils and fats.

Chelating agents (1-5%) – To prevent minerals in water from interfering.

Water (40-50%) – The solvent and carrier.

Summary of Key Functions:

Solubilizing oils and grease: Surfactants and solvents break the oil into smaller droplets, making them easier to clean off surfaces.

Emulsifying: Emulsifiers keep the oils suspended in the solution, preventing them from separating and re-depositing on cleaned surfaces.

Water softening: Ingredients like sodium tripolyphosphate soften water, allowing detergents and surfactants to work more effectively.

Stabilization: pH adjusters and chelating agents ensure the product remains effective and stable during use.

These components work synergistically to break down and remove oils, grease, and other contaminants