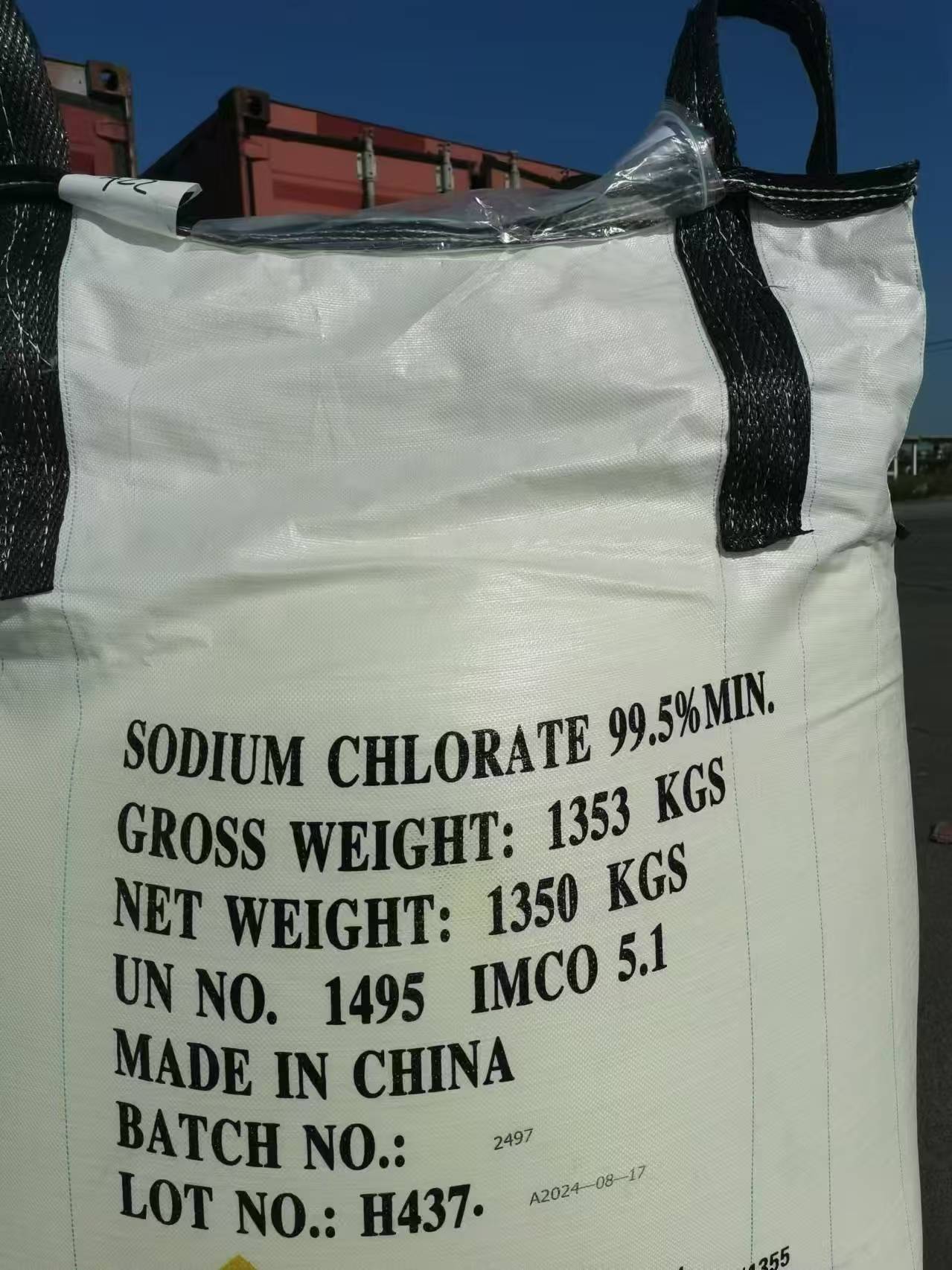

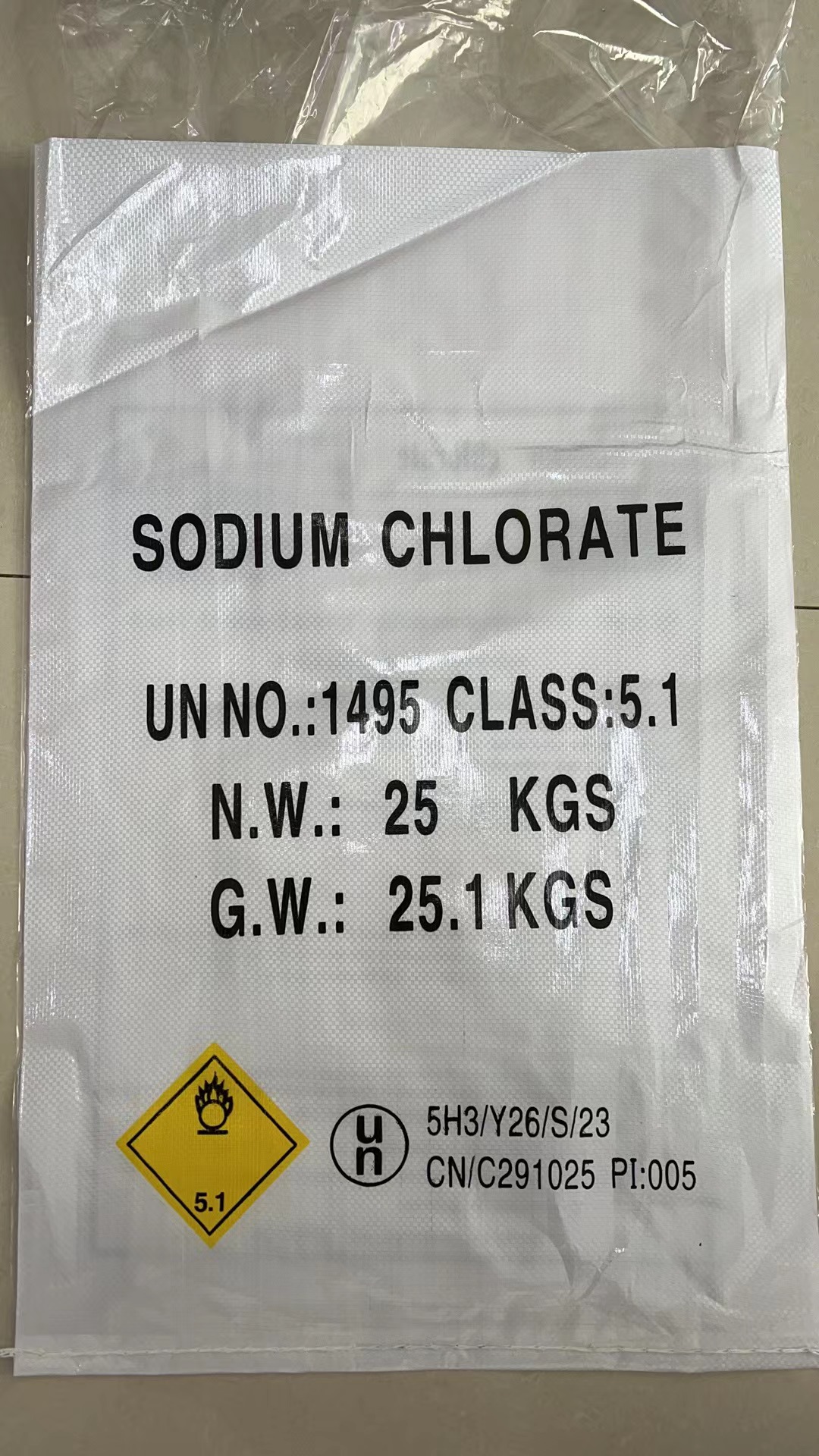

Sodium chlorate (NaClO₃) plays a crucial role in the production of bleached pulp through the chemical process known as chlorine dioxide (ClO₂) generation, used in kraft and sulfite pulping. Below is a breakdown of its application:

1. Chlorine Dioxide Production

Sodium chlorate is the primary chemical used to produce chlorine dioxide (ClO₂), a powerful oxidizing agent employed for bleaching pulp.

The generation process typically involves reacting sodium chlorate with a reducing agent, such as hydrogen peroxide, methanol, or sulfur dioxide (SO₂), in acidic conditions.

2. Bleaching Process in Pulp Production

Chlorine dioxide generated from sodium chlorate selectively removes lignin (the component that gives wood its color) while preserving the cellulose fibers.

It is primarily used in the Elemental Chlorine-Free (ECF) bleaching sequence, replacing elemental chlorine to reduce harmful environmental impacts, such as dioxin formation.

3. Advantages of Sodium Chlorate in Pulp Bleaching

Environmental benefits: Chlorine dioxide is less harmful than elemental chlorine, leading to reduced formation of toxic compounds.

High efficiency: Chlorine dioxide is highly effective in lignin removal, ensuring the pulp achieves a brighter color with minimal damage to fibers.

Cost-effectiveness: Sodium chlorate is relatively inexpensive and widely available.

4. Pulp Quality and Final Product

Bleached pulp produced using sodium chlorate-derived chlorine dioxide is used to manufacture high-quality paper products, such as tissue paper, office paper, and packaging materials.

In summary, sodium chlorate is critical for sustainable and high-quality pulp production, contributing to environmentally friendly practices while improving the brightness and quality of paper products.