Fermentation is a biotechnological process widely employed in various industries, including food and beverage production, pharmaceuticals, and biofuel manufacturing. Central to successful fermentation is the availability of essential nutrients that support the growth and metabolism of microorganisms responsible for the desired biochemical transformations. While organic nutrients such as sugars and amino acids are commonly utilized, inorganic nutrients play equally crucial roles in facilitating microbial growth and enhancing fermentation efficiency. This article explores the importance of inorganic nutrient supplements in fermentation processes and strategies for their optimization to maximize yield and quality.

The Role of Inorganic Nutrients in Fermentation: Inorganic nutrients, including minerals such as nitrogen, phosphorus, potassium, magnesium, and trace elements, serve as vital components of microbial growth media during fermentation. These nutrients are essential for various cellular processes, including enzyme activation, protein synthesis, energy metabolism, and maintenance of cellular osmotic balance. While microorganisms can often assimilate inorganic nutrients from the environment, supplementing fermentation media with specific inorganic nutrients can promote faster growth, higher cell densities, and increased productivity.

Optimizing Inorganic Nutrient Supplements:

Nitrogen Sources: Inorganic nitrogen sources such as ammonium salts (e.g., ammonium sulfate, ammonium acetate, ammonium formate, ammonium citrate etc.) and urea are commonly used to provide nitrogen for microbial protein synthesis. Selecting the appropriate nitrogen source and optimizing its concentration is crucial to achieving balanced growth and desired product formation. Additionally, nitrogen sources may influence the production of secondary metabolites, flavor compounds, and by-products in fermentation processes.

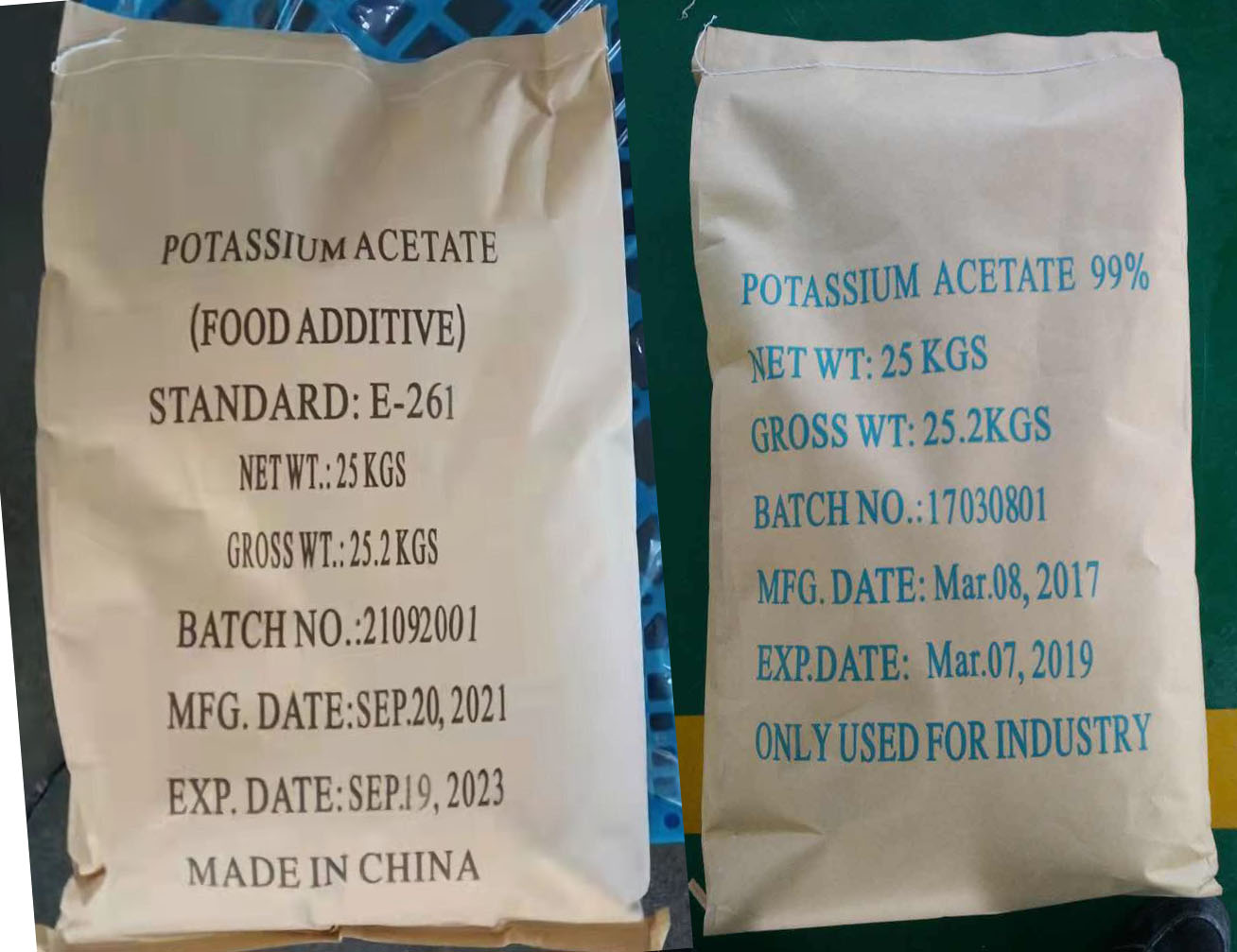

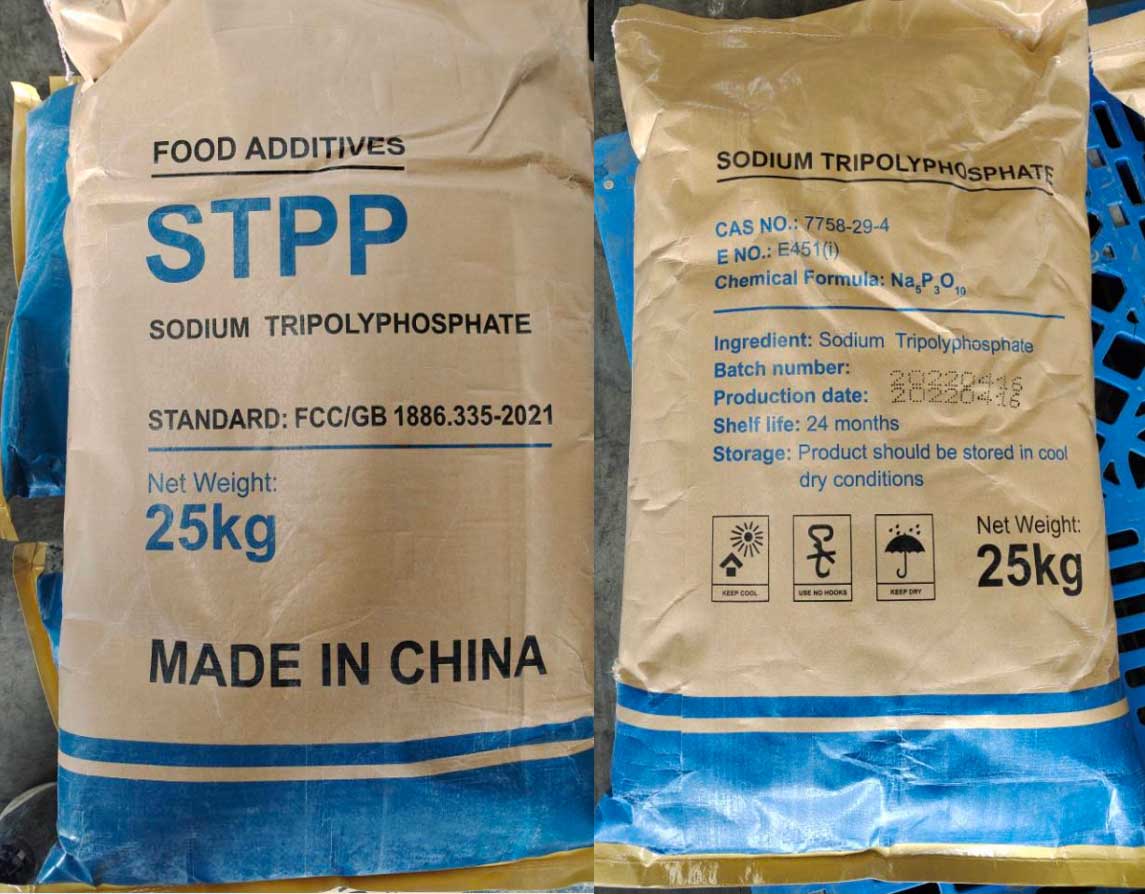

Phosphorus and Potassium: Phosphorus is essential for nucleic acid synthesis, energy metabolism, and cell membrane integrity, while potassium regulates enzyme activities and osmotic balance. Phosphate salts (e.g., monopotassium phosphate, dipotassium phosphate) and potassium salts (e.g., potassium chloride, potassium phosphate, potassium carbonate, potassium citrate) are commonly added to fermentation media to ensure adequate levels of these nutrients. Balancing phosphorus and potassium concentrations is essential for optimizing cell growth and metabolic activity.

Magnesium and Trace Elements: Magnesium ions (Mg2+) serve as cofactors for numerous enzymes involved in ATP metabolism, DNA replication, and cell signaling. Similarly, trace elements such as iron, zinc, manganese, copper, and molybdenum play critical roles in enzyme function and metabolic pathways. Supplementing fermentation media with magnesium sulfate and trace element solutions can improve cell viability, enzyme activity, and overall fermentation performance.

Applications in Industry: Inorganic nutrient supplements are extensively utilized in various industrial fermentation processes to enhance productivity, consistency, and product quality. In the production of alcoholic beverages, such as beer and wine, carefully balanced nutrient additions contribute to yeast health, fermentation kinetics, and flavor development. Similarly, in biopharmaceutical manufacturing, optimizing inorganic nutrient supplements is essential for maximizing the yield and purity of therapeutic proteins, antibiotics, and other biologics.

Conclusion: Inorganic nutrient supplements play indispensable roles in supporting microbial growth, metabolism, and product formation during fermentation processes. By understanding the specific nutrient requirements of target microorganisms and optimizing nutrient supplementation strategies, producers can achieve higher fermentation yields, improved product quality, and greater process efficiency. As the biotechnology industry continues to evolve, further research into the interactions between inorganic nutrients, microbial physiology, and fermentation kinetics will drive innovation and advancements in fermentation technology.