Ceramics, with their diverse applications ranging from kitchenware and tiles to advanced industrial components, have been an integral part of human civilization for centuries. The evolution of ceramic manufacturing processes has been marked by the incorporation of various additives to enhance properties such as strength, durability, and workability. One such additive that has gained prominence in the ceramic industry is Sodium Tripolyphosphate (STPP). This article explores the application of STPP in ceramics and its impact on the final product.

Understanding Sodium Tripolyphosphate (STPP):

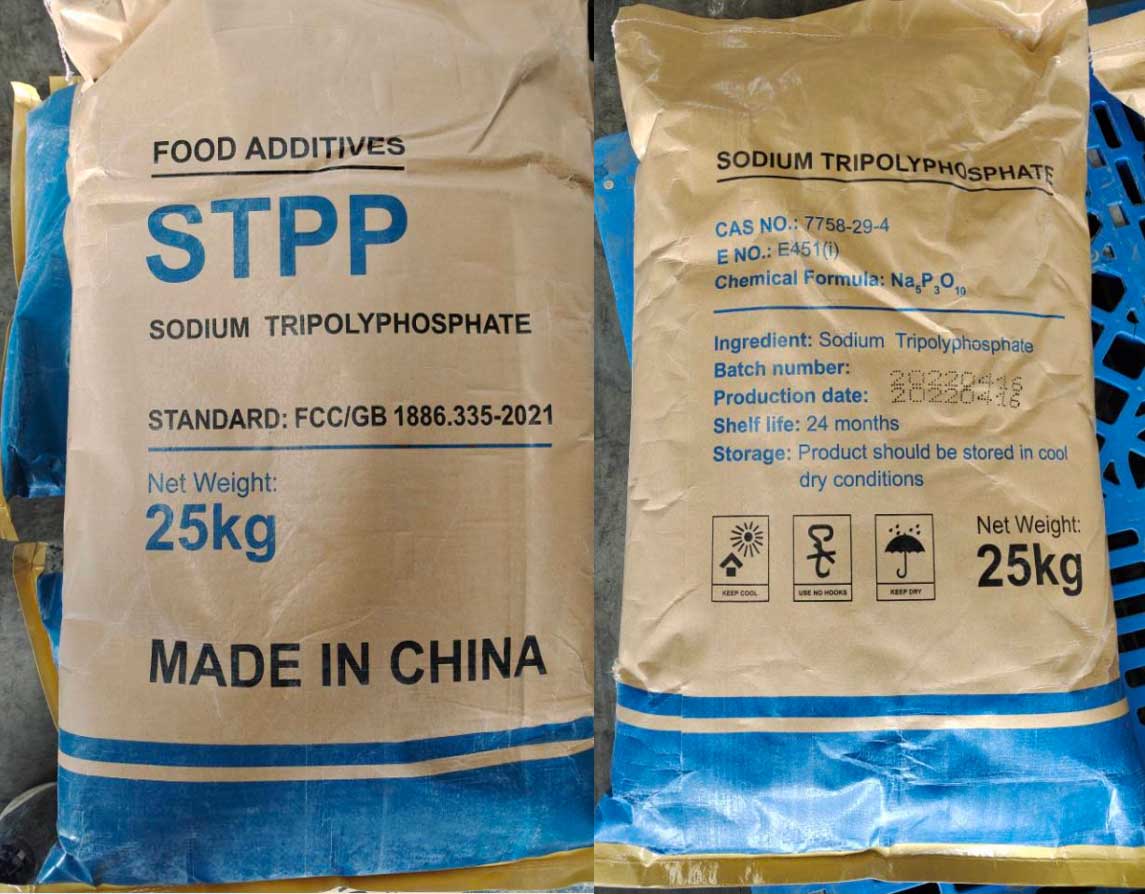

STPP is a white, crystalline powder that belongs to the family of polyphosphates. Its chemical formula is Na5P3O10, indicating that it is composed of five sodium ions (Na+) and three phosphate groups (PO4). STPP is water-soluble, making it easy to incorporate into aqueous ceramic formulations.

Applications of STPP in Ceramics:

Deflocculation and Suspension:STPP is widely used as a deflocculant in ceramic slips and glazes. Deflocculation involves dispersing particles to achieve a stable, homogenous suspension. By reducing the viscosity of the ceramic slurry, STPP facilitates better particle dispersion, preventing settling and enabling uniform coating on ceramic surfaces.

Improved Rheological Properties:Rheology, the study of the flow of matter, plays a crucial role in ceramic processing. STPP influences the rheological properties of ceramic slurries by enhancing their fluidity and reducing friction between particles. This results in improved workability during shaping processes such as casting and extrusion.

Enhanced Green Strength:Green strength refers to the strength of a ceramic body before firing. STPP can enhance green strength by promoting better particle packing in the unfired state. This is particularly beneficial in the production of complex shapes where maintaining structural integrity during handling and drying is crucial.

Prevention of Shrinkage and Cracking:The controlled release of water during the drying process is critical in preventing shrinkage and cracking of ceramic products. STPP helps in regulating the drying behavior by acting as a water retention agent. This ensures a more uniform drying rate, minimizing the risk of defects in the final product.

Improved Glaze Adhesion:In glaze formulations, STPP aids in achieving better adhesion to the ceramic surface. It promotes the formation of a stable glaze layer by preventing settling and separation of glaze particles. This results in a smoother and more consistent glaze finish.

Reduced Firing Temperature:STPP can contribute to lowering the firing temperature of ceramic bodies. This is particularly advantageous in energy savings and the production of specialized ceramics where high firing temperatures may not be desirable.

Conclusion:

Sodium Tripolyphosphate (STPP) has become a valuable additive in the ceramic industry, influencing various stages of ceramic processing from slip preparation to the firing stage. Its ability to enhance suspension, rheological properties, green strength, and glaze adhesion make it a versatile tool for ceramic manufacturers aiming to improve the overall quality and efficiency of their products. As technology continues to advance, the role of STPP in ceramics is likely to evolve, contributing to further innovations in the field.